Mining Wikipedia

Mining in the Philippines began around 1000 BC. The early Filipinos worked various mines of gold, silver, copper and iron. Jewels, gold ingots, chains, calombigas and ...

WhatsApp)

WhatsApp)

Mining in the Philippines began around 1000 BC. The early Filipinos worked various mines of gold, silver, copper and iron. Jewels, gold ingots, chains, calombigas and ...

Problem: Our customer in West Bengal, India, had a problem. He faced rising costs for iron ore and coke, the primary burden material for his blast furnaces.

From ore to metal Learn more about the exciting path of copper

Iron ore western centeral eastern Exploration Detail: 26km 8km This mine is one of the largest mineral areas in Iran, also considered to be one

Iron ore Mining Processing. Iron ore crushing is actually the preparation process that are needed for decreasing the size of iron ores during all iron ore processing ...

Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica ...

During the year ending June 2006, the mine handled of ore and waste and processed of sulphide ore grading % copper. Total mill output was 1,207,100 ...

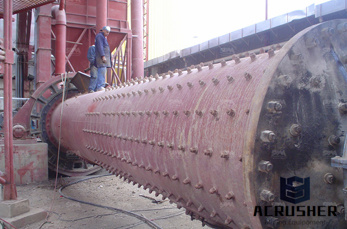

Autogenous and Semiautogenous mills. The AG/SAG mills are utilized to grind runofmine rock or primary crusher discharge.

Vale is the world''s biggest producer of iron ore and pellets, raw materials essential to the manufacture of steel. Iron ore is found in nature in the form of rocks ...

HS Code of Chapter 7325, List of Hs Codes for OTHER CAST ARTICLES OF IRON OR STEEL, Free Search Indian HS Classifications

Crushing plant and grinding mill are widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on.

pakistan crusher,stone crusher machine,quarry crusher crusher,iron ore crusher,gypsum crusher,cement grinding mill plant, marble grinding ball mill,stone crushing ore ...

Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals ...

An Educational Guide to Gold for Kids Facts about Gold. Gold, like no other metal, has a fascinating history and a special place ...

Use of Iron Ore Pellets in Blast Furnace Burden Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 ...

2 HPGR High pressure grinding roll for the minerals industry Introduction During its relatively short history in minerals processing, HPGR technology

Aluminum is manufactured in two phases: the Bayer process of refining the bauxite ore to obtain aluminum oxide, and the HallHeroult process of ...

Ore Processing International Chromium Development Association ©2011 ! Initial processing of chromite ores can be by hand sorting of lumpy .

Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh ...

Stirred Milling Technology Three features of stirred mills that transform the economics of fine grinding are : the high intensity attrition grinding environment

THE BASIC PROCESSES OF GOLD RECOVERY INTRODUCTION. Man has held a fascination with recovering and acquiring gold almost since the beginning of time.

Iron ore pelletizing. Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast ...

Applications: nano grinding, size reduction, homogenizing, mechanical alloying, colloidal milling, high energy comminution: Field of application: agriculture, biology ...

Crushing and grinding processes have undergone significant changes over the last 20 years. These adjustments have focused on lowering costs and increasing

WhatsApp)

WhatsApp)