Trends and developments in green cement and .

The cement industry faces a number of challenges that include depleting fossil fuel reserves, scarcity of raw materials, perpetually increasing demand for cements and ...

WhatsApp)

WhatsApp)

The cement industry faces a number of challenges that include depleting fossil fuel reserves, scarcity of raw materials, perpetually increasing demand for cements and ...

Concrete Batching Systems are a dedicated suppliers to the concrete industry. Focusing specifically on the needs of the customer, from specification, design, supply ...

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is ...

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

Concrete is a composite material composed of coarse aggregate bonded together with a fluid cement that hardens over time. Most concretes used are limebased concretes ...

sale buy used machinery, second hand machinery used steam boilers used chemical machinery used generators used plastic machinery used rubber machinery and .

Megatech Supplier of mini cement plants, industrial mini cement plants, cement making machines, industrial cement plants, vertical shaft kiln machine, industrial ...

Gypsum is a mineral and is hydrated calcium sulfate in chemical form. Gypsum plays a very important role in controlling the rate of hardening of the cement.

Mixing: Mixing is mankind''s oldest process. Mixtures allow for substances of the nature to be put to good use. Most food, personal hygiene products and remedies are ...

We produce a wide range of highalumina cements and calcium aluminate have customers in more than 60 countries around the world.

Concrete strength. Many factors influence the rate at which the strength of concrete increases after mixing. Some of these are discussed below. First, though a couple ...

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california

Frequently Asked Questions about Cement and Concrete Basics.

Though "cement" and "concrete" are often used interchangeably, concrete is actually the final product made from cement. The primary component of cement is ...

Basic Definitions and Terminology. Concrete is composite material, meaning that it is made up of more than one type of material at the macroscopic scale.

How is cement manufactured? Learn cement manufacturing process thoroughly.

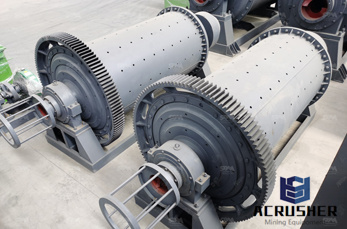

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

Drying and Primary Grinding. The essential additives quartz, sand and iron ore are added to the homogenised material and this mixture is then ground to a powder with ...

Summarises the hydration process of Portland cement and describes the principal cement hydration products.

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

I was TERRIFIED to pour self levelling cement over my kitchen floor but after reading a ton about it online I did it. And it worked GREAT. Tutorial here.

Design and Control of Concrete Mixtures, 16th edition: Media Type: Print: Every industry has one outstanding reference book, and for concrete it is Design and Control ...

REGULAR ARTICLES . Performance analysis of magnesium phosphate cement mortar containing grinding dust . Daniel Véras Ribeiro *; Márcio Raymundo Morelli

Cement Production Process Three production steps are distinguished in the description of the production of cement: zPreparing raw materials: Mixing/homogenising ...

WhatsApp)

WhatsApp)